QUESTION:

What kind of low alloy steel do you see in the attached pictures, which are optical micrographs of Widmanstatten Ferrite?

Chemical analysis: Fe-0.032C-0.2Ni wt%. The inclusions are chromite and (Fe,Mn)S.

What is your opinion about the cooling process?. How long does it take to form this microstructure?

ANSWER

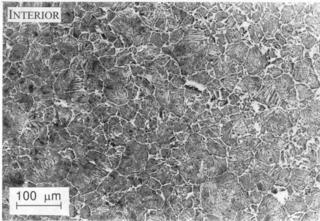

The excellent micrographs you sent are illustrated (above); they can be magnified by clicking on the thumbnails.

First thing to emphasise is that your steel has a very low carbon concentration, which means that it will transform rapidly during cooling. Secondly, the austenite grain size is very large, thousands of micrometers in size. This is very important, because a large austenite grain size favours the development of Widmanstätten ferrite at the expense of allotriomorphic ferrite.

The very large austenite grain size means that you must have austenitised the sample at a very high temperature.

It is hard to guess the cooling conditions, but the layer of allotriomorphic ferrite at the austenite grain boundaries is quite thin, which means that the samples will have been cooled relatively rapidly. Notice also that the pearlite between the Widmanstätten ferrite plates is very fine, and cannot easily be resolved, consistent with a relatively high cooling rate.

You also asked about the growth rate of Widmanstätten ferrite - it is a paraequilibrium displacive transformation so the lengthening rate of the plate in a steel such as yours can be many hundreds of micrometers per second, which means that the microstructure probably developed within a second or so once the transformation began.

Harry Bhadeshia, at University of Cambridge, UK.

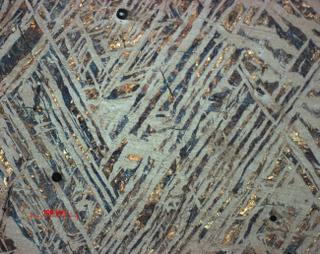

NOTE: The following microphoto shows the current steel of an airplane turbine; photo that was carried out at University of Cambridge. Although photos have the same size and scale, please, note the difference in size of Widmanstatten ferrite plates in both micrographs; the first one regarding to VEAS-01 (above), and the second one concernig the turbine (below):